Products originates from design

For LED light, we mainly considerate from the light, electricity, heat, appearance, process convenience, quality control, installation convenience and other aspects to meet customer needs to meet customer demand in the research and development process

- 1.Light: Light is light from a led light, consider the lighting use environment, to meet the standard of use of illumination, to avoid light pollution, also meets the protection of the human eye.

For functional luminaires,consider that led light have this function, such as led plant lights, pork lamps, medical lamps, etc., to achieve spectral effect to meet the needs of guests

- 2.Electricity,electricity refers to the electrical part of the light,Consider the electrical part of the lamp, which meets the relevant standards, EMI, EMC, life, reliability are all need to be considered to ensure that the products delivered to the customer are safe and reliable

- 3.Thermal, due to the characteristics of led semiconductors, the design of lamps on the treatment of heat is particularly important, the use of conduction, radiation, convection, timely release of led and power parts of the heat, led luminaires reliability, life, have helped to deliver customers’ products safe and reliable

- 4.Appearance,consider the appearance and the industrial design of led light when design a light , to make the light look simple and beautiful.It’s something that needs to be accumulated and pondered over a long period of time.Our company’s core research and development team has a long time, rich experience, to meet the aesthetic needs of clients.

- 5.Process convenience, when in the design of lights,considering bulk manufacturing ,also easy to produce, need effectively control the quality rate, improve production efficiency, and thus reduce costs, so that the products delivered to the clients with long use life and reasonable price.

- 6.Quality, Quality comes from design. material selection in design stage , reliability, quality testing convenience and the ultimate quality of the product, cost and design are closely related. we fully consider these elements in design products , to ensure can design a good products which both meet client’s requirements and standards

- 7.Consider the extensibility of the product when developing and designing the product. A product accessories can be used in different products compatible, can effectively reduce costs, and thus reduce prices, give guests preferential.

LED lamps are composed of various systems, electronic hardware, software, pcb, structural appearance, heat dissipation, process, quality, cost, light, electricity, heat and others common composition of a light. Design needs to be comprehensive consideration,also balanced, compatible, to achieve the best price/performance ratio.

That's what we do.

Research and development design of the electronic part

A:LED pcb Research and development design

- 1.Understand the overall electrical requirements of the luminaires your customers expect.

We determine the specific power, voltage, and circuit mode of the lamp according to the voltage, international standards of the customer’s country, combined with the thermal conditions of the housing.

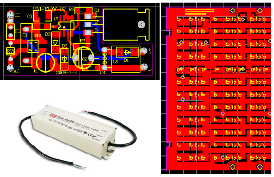

- 2.Use software such as protel to design circuit diagrams, PCB diagrams

In the design of pcb diagram, including electronic device selection, spacing, thermal guide, line mode, test bit, machine identification bit, assembly bit, etc. affect the lamp performance, cost, assembly, test elements integrated and designed into the PCB

- 3.Confirm PCB material (the difference of sheet material is related to cost, heat dissipation and performance)

- 4.With pcb producers to determine the PCB plate material, paint color, copper foil thickness and other specific pcb production requirements.

- 5.Production of samples, assembly of electronic components, test verification, if not used to achieve the design purpose, then adjust the modification, if the purpose is achieved, then assembled into a finished product, as a standard to confirm to the customer.

- 6.According to the confirmed results of the production of inspection standards, production process.

B: LED Power Design – Selection

- 1.For our own design of the diver, according to the PCB design of the corresponding PCB, choose the appropriate housing, terminals, harnesses, assembly, water-resistant treatment as needed

- 2.After assembly is complete, test verification, aging, reliability, EMI/EMC and electrical parameters testing

- 3.For the purchase driven power supply, make selection according to the light source, lamp housing, related standards etc .next make the related tests,such as aging, reliability, EMI/EMC, heat dissipation, waterproofing and electrical parameters,assembly it into finished lamps after testing qualified.

- 4.The luminaire overview for aging, reliability, EMI/EMC, thermal, waterproof and electrical parameters related to the test ,double confirmation once again.

- 5.Make the production process,test standards according to the confirmed results.

C.Design programming of controllers, design and development

- 1.For the ourselves led light control system,assemble the components on the PCB after PCB design completed,written the related program in to the

relevant IC with the program burner(above picture),and assembled the IC on the PCB

- 2.Make reliability test,such as EMI/EMC, interference, waterproofing, electrical parameters, cascading installation method debugging, test confirmation

- 3.For the purchased control system, first the reliability of the control system, EMI/EMC, interference, waterproofing, electrical parameters test, and then combined to our luminaire products, and once again the entire lamp and control system reliability, EMI/EMC, interference, waterproofing, electrical parameters, cascading mode, etc.

- 4.Once the confirmation is complete, make a video of the effect and send it to the customer for determination.

5.Make inspection standards, process documents

Research and development design of the structural part

- 1.Understand the overall customer’s needs, including expected results, including electrical, lighting, use environment and application location, water resistance requirements, etc.

- 2.Full consideration of human aesthetics and artistry, the use of CAD, Pro-E and other design software to design the overall appearance of the product, to the customer selected (self-designed products, need to design a different look, selected by the internal staff vote)

- 3.The design of the selected appearance of the product to be refined, in the design to take full account of the production, cooling, waterproofing, optical treatment, materials, processing technology, mold and other elements

Use Pro-E software to create source files

- 4.Thermal simulation and analysis of the resulting structural files using simulation software such as ansys

- 5.Theoretically achieve the design effect, make a hand board or 3d print out the model to test the actual effect

- 6.Production of molds, and mold factory to determine inspection standards

- 7.Identify the template with the customer, get customer feedback, and again with the mold factory double determination

*

Since the structural housing is not separately handed over to the customer, electronic, optical, waterproof and other parts are integrated to the customer, therefore, when testing verification, in addition to the test structure part of the requirements, it is necessary to say that other parts are assembled together, the overall lamp for relevant test verification.

Research and development design of the optical part

Optic lens Research and development design

A.LED lens design and development

- 1.Understand the overall lighting needs of customers, including their desired effect,

uniformity, angle, spot etc. Or know the used environment and application place,

we help customers to confirm these overall lighting effect according relevant international standards.

2. Know the led which client use, include led brand, model no, type etc, or according 1 recommend led

3. According lighting distribution curve, spectral characteristic design and make light source files.

4. According client request, confirm the material ,or we advise use which kind material according material

characteristic(PC/PMMA/GLASS ETC)

5. Confirm with customer, what is the lens effect does they need, such as clear, frosted ,milk white etc.

6. Design drawing files(Use Proe software design models, use light tools and Tracepro software make optical analysis.

7. Export the IES files, use Dialux software make simulation and analysis, or make hand sample for test the effect.

If not achieve the desired effect, need adjust modify, if ok, then make mold.

8. We confirm the mass production sample with lens factory, confirm the quality standards,mark the unacceptable quality point.

9. Confirm the mass production sample with clients, get clients feedback, and double confirm with factory again.

B:Auxiliary light design

- Auxiliary light design, mainly using different materials, LED light out of secondary processing, such as the use of different materials of the film, light reflection, scattering, refraction.

- Use paint, reflector to reflect light, refractive treatment, the use of optical fiber and other devices for light conduction.

C:Other optical designs

- Mainly from the transmission of light, reflection, refraction, scattering to design optical parts, there are many optical treatment is designed in the shell structure part, the design of the part refers to the structure part of the design.

General

LED luminaire electronics, structure, appearance, optical design, thermal design, waterproof, processing and assembly, testing convenience, materials, etc. need to be considered comprehensively, our company’s core research and development team members in the LED industry has more than 10 years of experience, for the lamp design has a wealth of experience, to meet customer needs

Reliability detection of The R-D

Smart power meter

We use a power meter to measure the electrical parameters of the lamp, including power, current, and voltage.

Multimeter

We use a universal meter to measure PCB breaks, current voltages, component parameters

AC adjustable power supply

We use AC adjustable power supply to simulate lamps using electrical environments, e.g. 110V, 230V different input voltages

Photoelectric integral ball

We use integral balls to measure the spectral parameters of lamp beads and lamps

Illumination meter

We use an illumination meter to measure the illumination of the lamp

Micromagscopic

We use a micromagscopic magnifying glass to measure led beads, chips and compositional materials

Single-point thermometer

We use a single-point thermometer to measure LED junction temperature

Multi-point thermometer

We use a multi-point thermometer to measure thermal heat control in different parts of the lamp.

Imitation impact instruments

Due to the moment of the lamp switch, electrical parameters will change, we use imitation switch instruments to simulate on-off action, measuring the electrical parameters of the lamp changes

DC adjustable power supply

We use DC adjustable power supplies to simulate low voltage products such as DC12V, DC24V, DC5V, etc.

Fluke Universal Watch

We use the Fluke universal table to measure electrical parameters with high accuracy

Long-term aging rack

Use the long-term aging rack for 1 hour, 4 hours, 8 hours, 24 hours, 1000 hours of uninterrupted lighting aging testing

Various rulers

We use a variety of gauges to measure the size of lamps and components

Waterproofing test

We use showers, containers, etc. to make initial measurements of the lamp’s protection level

Scale

Measure the weight of lamps and components with electronic scales

Other tests

Due to the low frequency of use, we work with other third-party laboratories for testing, including TUV, UL, etc

Samples, documents and data management

1.All customer samples, are stored in special sample cabinets as required, do a good job of marking, moisture-proof waterproof, sealed packaging

2.All customer samples, if the need for anatomy, before anatomy, measured parameters, complete samples and semi-finished samples are photographed and retained, the final raw materials also need to be marked, sealed packaging preservation

3.All samples given to the customer, are carefully filled in the measurement parameters, take pictures to save, if necessary, need to make two copies, one to the customer, one to save

4.All sample parameters, photos, all need to print a copy of the preservation, an electronic file to save

5.All samples that need to be loaned to the quality department or material supplier, against the quality level of the parameters, need to be registered, and restitution, after return also need to do a good job of marking, proper preservation.